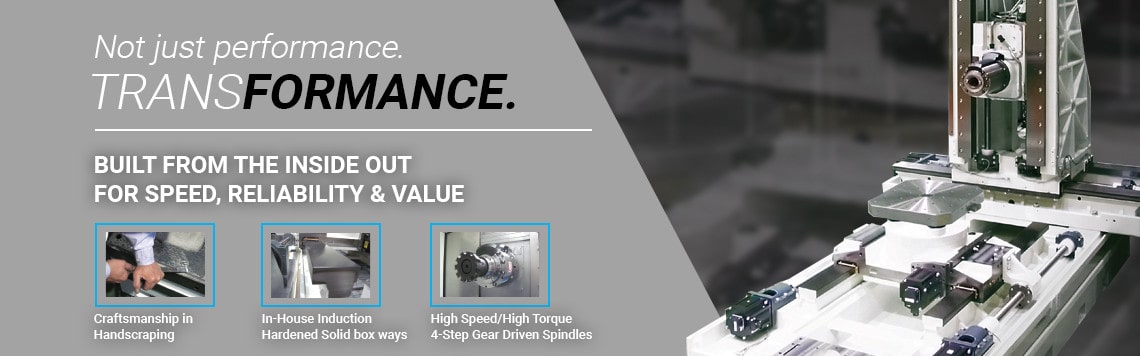

Kitamura Machinery has been a leading manufacturer of machining centers worldwide for more than 90 years. Our innovative line of machining centers includes horizontal, vertical, 5-axis and double column machining centers that are designed to meet the highest demands of manufacturers worldwide. With decades of hands-on experience and a focus on cutting-edge CNC technology, Kitamura Machinery delivers machining centers that offer improved productivity, easy adaptability, reduced defects and precise, reliable long-term performance.

At Kitamura, customer service is a top priority. We are committed to providing the most knowledgeable and responsive machining center service and support to customers throughout the United States and around the world. This commitment to quality, performance and value is at the heart of everything we do.

Kitamura Worldwide

(Head Office & Works)

1870-Toide, Takaoka-City

Toyama Pref., Japan

Tel.: +81 766 63 1100

(U.S. Headquarters)

Wahlerstrasse 39, 40472 Dusseldorf, Germany

Tel.: +49 211 657 9010

www.kitamura-machinery.deE-mail: info@kitamura-machinery.eu

1-23-18, Kanaya, Moriyama-ku

Nagoya City, JapanTel.: (052)795-3655

5-21-8 Esakacho, Suita-shi

Osaka City, JapanTel.: (06)6309-8680

4-19-11 Kamezawa, Sumida-ku,

Tokyo, Japan, 130-0014

Tel.: (03)5619-1250