Setting the Global Standard in Machining Excellence

Kitamura Machinery stands at the forefront of the machining industry, celebrated worldwide for its unwavering dedication to innovation, precision, and durability. Since our inception in 1933, Kitamura has continuously redefined high-performance machining centers. Our machines, renowned across the Americas, Europe, and Asia, embody a legacy of excellence, serving diverse industries with cutting-edge technology and unmatched reliability.

Craftsmanship

Precision-Driven

Machine Design

A machine’s design directly impacts its accuracy, stability, and performance. Kitamura’s True Geometric Accuracy (TGA) ensures tight tolerances, peak productivity, and long-term reliability.

The Art of

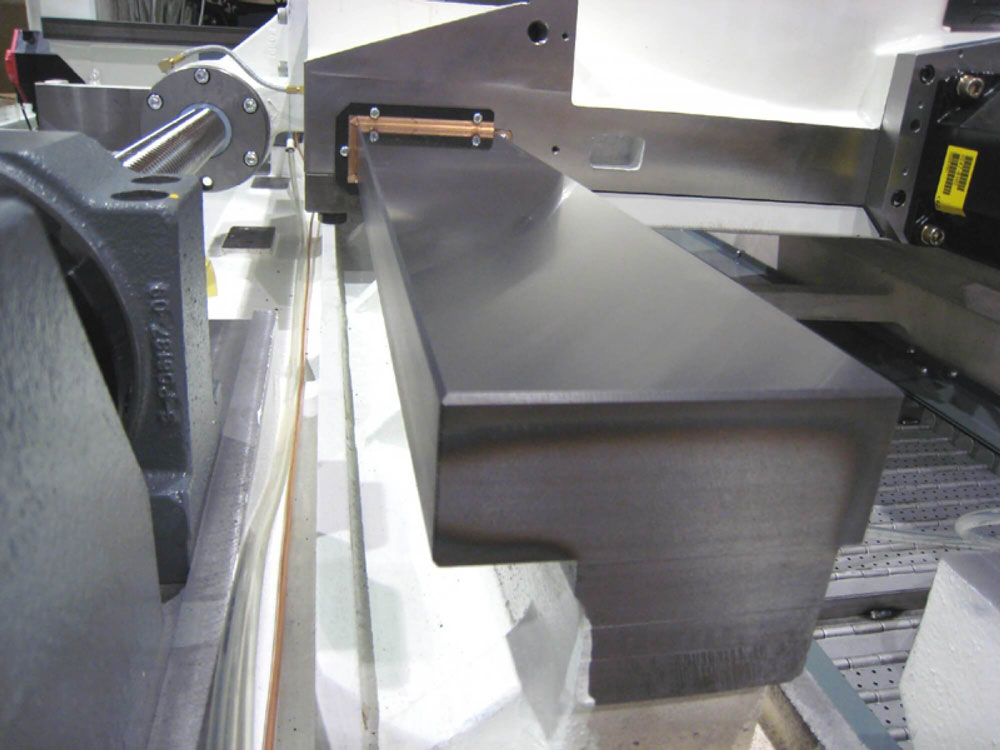

Hand Scraping

Kitamura’s hand scraping process guarantees a precision fit that machines alone cannot achieve. Critical machine contact surfaces are meticulously scraped by expert technicians, ensuring unmatched accuracy and longevity.

Consistent Accuracy

& Performance

Hand scraping and precise hand-fitting allow Kitamura machines to achieve ±0.002mm full stroke accuracy and ±0.001mm repeatability, ensuring superior machining results without electronic compensation.

Built for Strength

& Durability

Kitamura machines are crafted using Meehanite cast iron and induction-hardened, precision-ground solid boxways, providing the mass, stability, and damping needed to withstand extreme cutting conditions.

Rigidity

Unmatched Rigidity for

Superior Performance

Kitamura machines are built for maximum rigidity, ensuring long tool life and peak accuracy. Solid column construction, high-grade Meehanite casting, and precision-ground box guideways minimize vibration and enhance durability.

Meehanite Cast Iron

– Built for Strength

GA50 Meehanite cast iron in the bed, column, saddle, table, and headstock delivers unmatched vibration absorption and stability, maintaining ultra-high accuracy of ±0.002mm full stroke.

Precision-Engineered

Box Guideways

Solid box ways provide full surface contact for heavy loads and extreme cutting conditions. With superior anti-vibration capabilities and world-leading rapid feedrates of 60m/min (2,362 ipm), they ensure exceptional machining efficiency and tool life.

Exclusive Thick-Wall & Ribbed Construction

Kitamura’s unique thick-walled design enables deeper, more stable cuts with superior strength and reliability. Distortion-free components ensure long-term precision and performance.

Performance

High-Performance

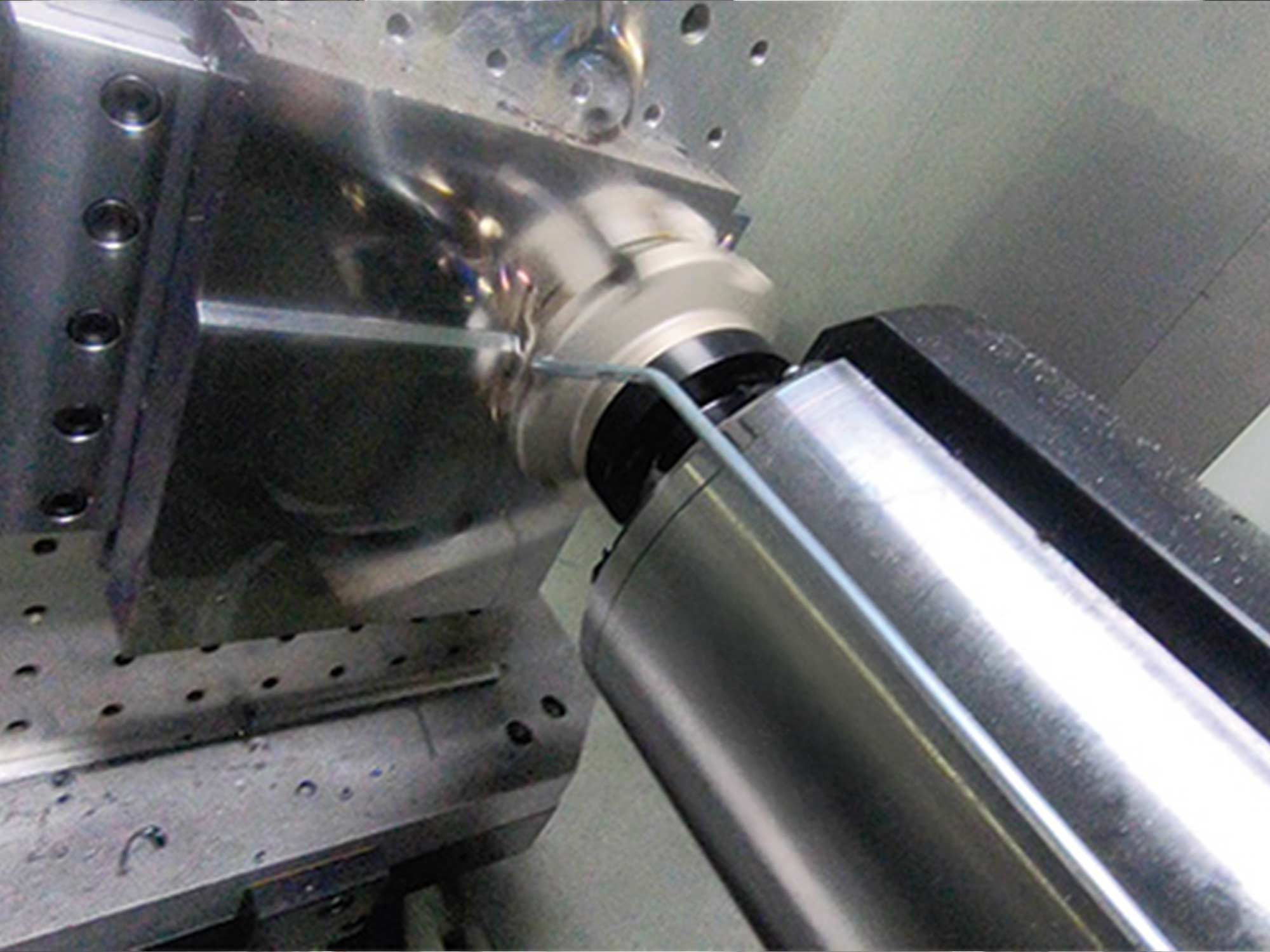

Gear-Driven Spindles

Kitamura’s multi-step gear-driven spindles deliver high-efficiency cutting with low energy consumption. The efficient oil chiller system minimizes thermal displacement, extending spindle life and ensuring superior accuracy and stability.

Advancing Spindle

& Rapid Feed Technology

Since 1992, Kitamura has continuously pushed spindle performance, introducing the world’s fastest 4-step gear-driven spindles. Rapid feed rates on solid box ways have evolved from 24m/min in 1991 to an industry-leading 60m/min today.

Flexible Workpiece Handling for Maximum Efficiency

Kitamura’s multi-pallet systems reduce setup time, manpower, and tooling costs. These systems are customizable, easily expandable, and designed to support unmanned machining for both small and large-scale operations.

Patented Fixed-Pot ATC for Continuous Productivity

Kitamura’s high-speed “Fixed-Pot” ATC system minimizes downtime by preparing the next tool while machining. Expandable up to 300 tools, it increases efficiency, machining uptime, and supports lights-out production.

Speed and Accuracy

Ultra-Precise Multi-Step Gear Driven Spindles

Kitamura’s 4-step gear-driven spindles deliver speeds up to 20,000 rpm while maintaining strong low-end torque and fine-finish capabilities. The shockless drive mechanism minimizes vibration, and the exclusive headstock design eliminates heat transfer to spindle bearings, ensuring maximum accuracy and rigidity.

World’s Fastest Rapids

on Solid Box Ways

Kitamura leads the industry with rapid speeds of 60m/min (2,362 ipm) on solid box ways. Patented twin ballscrew and dual-feedback technology drive unmatched acceleration, feedrates, and precision, optimizing high-speed machining performance.

Advanced 67-Million

Pulse Encoder Technology

The combination of fine-pitch ballscrews and 67-million pulse encoder technology delivers up to 4x smoother surface finishes, while ensuring exceptional accuracy and precision.

Intelligent Advanced Control (IAC) for Thermal Stability

Kitamura’s IAC system consists of a series of strategically located sensors and machine efficiency monitors that work to keep component growth due to machining heat build-up to less than ±5 microns.

SustainableManufacturing

At Kitamura, we champion a greener, healthier environment. Our commitment to sustainable innovation is prioritized through our use of reusable and repairable machine components, derived from clean resources. By minimizing waste and carbon emissions, we achieve excellence without sacrificing environmental sustainability.

Kitamura has and continues to innovate “ecologically friendly” technology into our machines. Our unique gear driven spindles “Sip” energy when compared to other spindle designs yet deliver more cutting power. This design has earned Kitamura the coveted “20th Japan Industrial Machining Union Chairman Award” for the best energy-saving machine tool technology.