Legacy of Excellence

The company motto “Limitless Creativity” lends itself to our commitment to consistent product development, allowing us to provide the most technologically advanced and reliable machining centers on the market today.

For over 90 years, Kitamura Machinery has created innovative machining centers that meet the strictest demands of manufacturers worldwide. By combining the best practices from decades of hands-on experience, extreme personal attention to detail and the latest technology advances, Kitamura Machinery has created a line of horizontal, vertical and 5-axis machining centers that provide customers with improved productivity through easy adaptability, reductions in defects, and accurate, reliable long-term performance.

Family owned and operated since 1933, Kitamura has always placed customer service at the core of its mission. Across the U.S. and around the globe, customers benefit from the most knowledgeable machining-center service and support teams in the industry. Kitamura’s deep focus on R&D has driven steady innovation, with more than 200 patents and patents pending in machining center design, demonstrating a lasting commitment to quality, performance, and value.

Our Timeline

Founded

Kitamura’s origins trace back to 1933, when it was founded by Mr. Genji Kitamura in Kanayamachi, Takaoka City, Toyama Prefecture, under the name Kitamura Iron Works. The company began its manufacturing journey through a sub-contracting partnership with Komatsu Ltd., producing paper pulp machinery, a foundational step that laid the groundwork for Kitamura’s future in precision engineering. This early experience not only instilled a commitment to quality and craftsmanship but also marked the beginning of a long tradition of serving demanding industries with technically advanced solutions.

Limitless Creativity

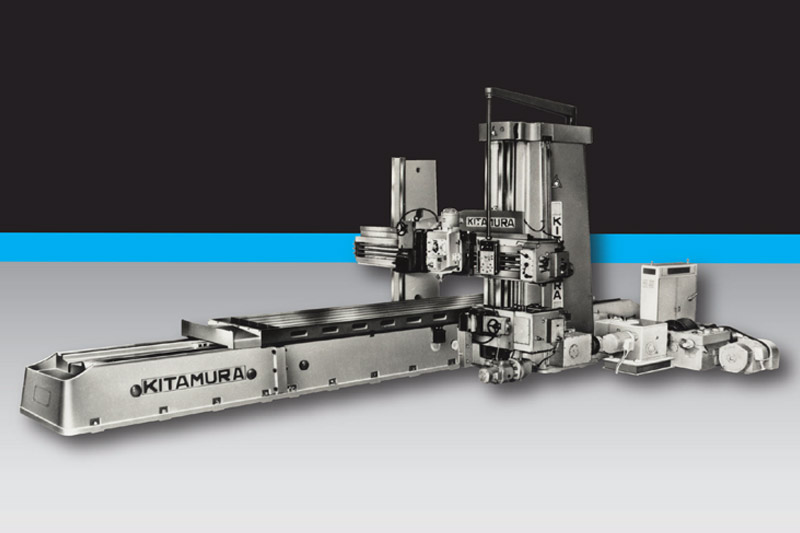

In the 1960s, Kitamura shifted its focus towards planers as a strategic avenue for growth, swiftly rising to become the leading manufacturer of planers in the domestic market. Building on this success, Kitamura pioneered the development of the plano-miller, a groundbreaking innovation that seamlessly integrated the robust capabilities of both planers and milling machines. This heavy-duty, large-scale machine not only underscored Kitamura’s engineering prowess but also solidified their position as innovators in precision milling, boring and grinding machine tool technology.

VMC Breakthroughs

The 1970s brought Kitamura to a new level of advancement with the development of our first Vertical Machining Centers.

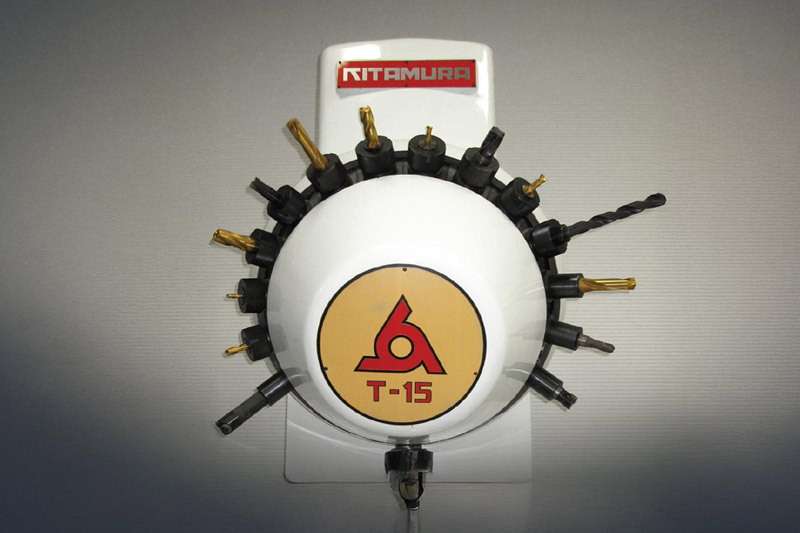

Inspired by the multi-armed design of the Senju-Kannon statue, Kitamura introduced the ultra-fast ATC (Automatic Tool Changer) concept, bringing to market the T-12, T-15, and T-20 VMCs — each machine building upon the technologies of its predecessor.

With patents secured and awards received for these innovations, Kitamura began focusing its efforts on machining center manufacturing well ahead of its competitors, establishing itself as a leader in high-accuracy, high-quality machine tools.

5-Axis Pioneers

The 1980s propelled Kitamura into the development of fully automated Vertical and Horizontal Machining Centers, with a focus on high speed and high-quality standard features that would soon become a cornerstone of the Kitamura brand.

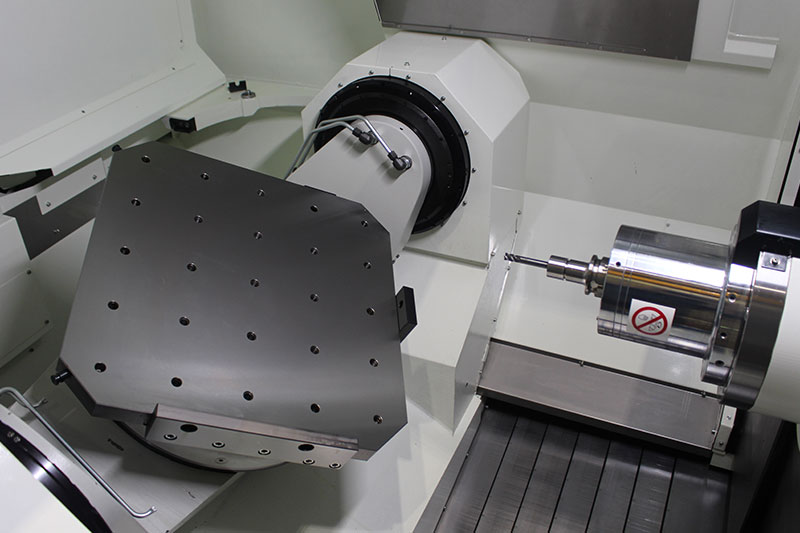

The development of the SUPERCELL-300 — the first of its kind in the world — brought Kitamura to the forefront of 5-axis automated machining.

Far ahead of its time, Kitamura has continued to build upon these innovations with new advancements in vertical and horizontal 5-axis unmanned machining.

Precision & Power

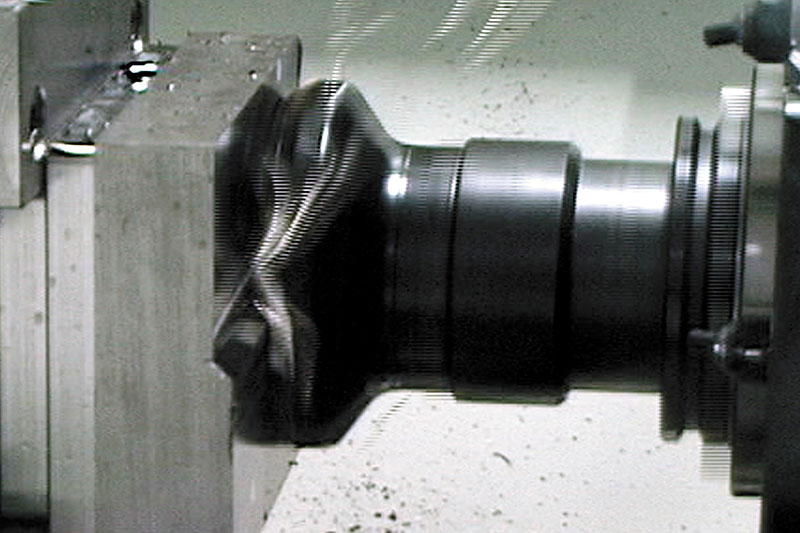

The 90’s saw a focus on rigidity in machine construction and high speed spindle technology. Kitamura builds upon box way technology and reaches 1,969ipm rapid feed rates, the fastest available at the time on solid box ways. R & D into speed and high precision continues with gear driven spindle development, reaching 20,000rpm spindle speeds soon to be brought to market. Patented twin ballscrew and dual feedback technology is introduced as an ultra-high precision base component for Kitamura’s heavy duty line of horizontal machining centers. TGA-Series machining centers are built on the premise of accuracy, speed and truth in machine design and manufacture.

Expansion Boom

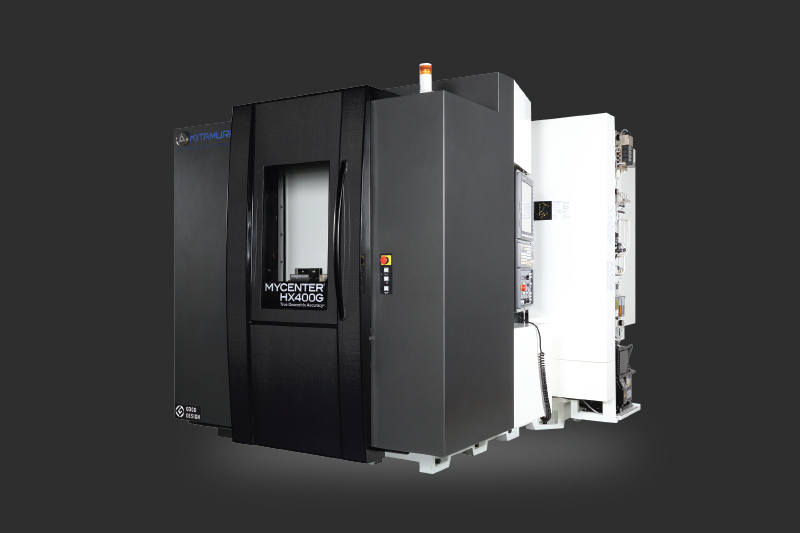

Kitamura manufacturers and produces its first 5-axis VMC (Mytrunnion-5) and introduces to market its “F” and “H”-Series Vertical and Horizontal Machining Centers with accuracies of up to +/-0.00004″ Full Stroke. Larger machining centers are in demand and Kitamura answers with an expansion of the Takaoka City Headquarters. With growth, Kitamura as a company continues to focus on highly accurate, well-built machining centers and research into ever expanding multi axis technologies and new machine configurations. The newly designed “G”-Series machining centers give Kitamura a fresh new look with feature rich functions and recognition for outstanding machine design. World’s fastest rapid feed rates of 2,362ipm on solid box ways are achieved. Introduction of Kitamura’s very own CNC Controller, the Arumatik-Mi, continues the company’s enthusiastic pursuit of machine tool development and production and offers customers a faster, more visual, user-friendly option for optimizing machine performance.

Machining Challenges Simplified

In this era, Kitamura introduced a fresh brand identity with the new tagline: “Machining Challenges – Simplified.” This message reflects our unwavering commitment to building machining centers that not only meet the complex demands of modern manufacturing but also make our customers’ jobs easier to master. Our proprietary Arumatik-Mi CNC control emerged as the industry standard for intuitive, icon-driven operation—bringing intelligent simplicity to the forefront of precision machining. We placed renewed emphasis on compact machine footprints, maximizing productivity while conserving valuable floor space. Field-expandable pallet pools and tool changers offered scalable flexibility to match growing customer demands. The further development of our Supercell series 5-axis horizontal machining centers marked a new chapter in high-precision automation. To complement this, we launched Anywhere Remote, our IoT-based monitoring solution that delivers machine status updates via email—giving customers real-time insight into their operations from virtually anywhere.

Future-Ready

The 2020s marked a milestone decade as Kitamura proudly celebrated 90 years of manufacturing excellence. In response to the growing demand for advanced multi-axis solutions, we expanded our lineup with new, larger 5-axis machining platforms, along with field-expandable pallet pools and tool capacity upgrades for our ultra-compact MedCenter5AX—further strengthening our position as a leader in high-precision, space-saving machining. In a groundbreaking collaboration with NTT DoCoMo, we launched the Kitamura Innovation Factory at our Japan Head Office and Works. This initiative promoted our Auto Part Producer software – a revolutionary tool that empowers users with no prior machining experience to easily process parts, lowering the barrier to entry in high-tech manufacturing. As demand surged across the U.S., Mexico, and South America, we relocated and expanded our U.S. Corporate Headquarters to better support our growing customer base. Continued advancements to our Arumatik-Mi control and ongoing industry accolades throughout the decade further underscored our commitment to driving innovation in the global manufacturing landscape.

Simplifying the Complex

As global manufacturing demands evolve, Kitamura continues to push the boundaries of precision machining with a focus on customer-driven innovation, compact automation, and digital connectivity. In response to increasing demand for flexible, space-efficient production, we’ve advanced our Supercell-300G—a fully integrated, ultra-compact 5-axis automation platform—designed to maximize productivity with minimal footprint. On the larger scale, the introduction of the Supercell-1000G 5-axis horizontal machining center reflects our commitment to supporting customers machining larger, more complex parts with greater accuracy and efficiency. Our ongoing developments in 5-axis machining, IoT integration, and the continued evolution of our Arumatik-Mi control keep us at the forefront of modern manufacturing. Backed by Made-in-Japan quality and a growing global support network, Kitamura remains focused on delivering high-performance solutions that simplify complexity and empower customers to meet the evolving demands of tomorrow—one challenge at a time.

Kitamura Company Principle

By attending to our customers with sincerity all of the time, we will work diligently to promote our products and obtain the highest confidence of Kitamura and its brand in the world.

To honestly take the lead in this age and at all times, we will put forth our best efforts to develop our abilities and new, innovative products in order to build a bright future.

We will always remember the initial effort and pioneering spirit, which serve as the foundation of Kitamura. In achieving growth and expansion of our company, we will return to the public the outcome of our best efforts..