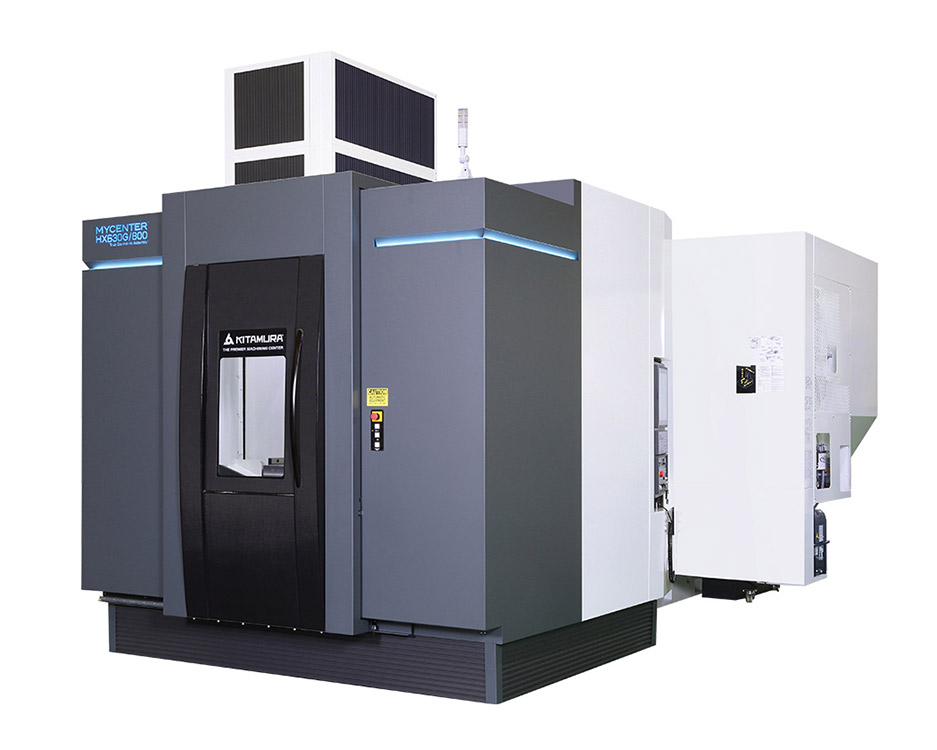

Mytrunnion-4G

Vertical 5-Axis Machining Center

The Mytrunnion-4G 5-axis vertical machining center surpasses competitors with its robust symmetrical build and exceptional, stable accuracy across the entire work area, ideal for machining highly intricate part geometries.

Specifications

Product Detail

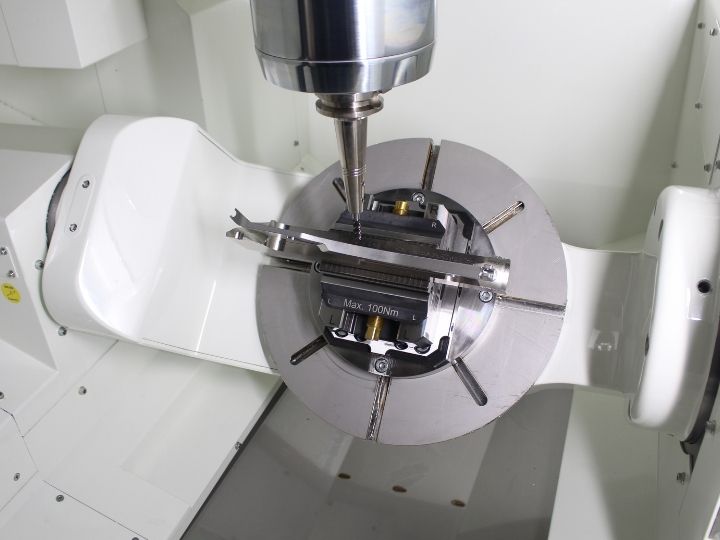

The Mytrunnion-4G 5-axis simultaneous machining center has been designed for high precision machining of medium to small multi-sided parts. The maximum work size of Ø19.7 x 15.7” high and table load capacity of 440Lbs allows for easy and more productive processing of parts in a single set-up. Guaranteed Kitamura quality and value combine to ensure high levels of quality and rigidity for unbeatable tool life and ultra-high-level accuracies for complex part machining.

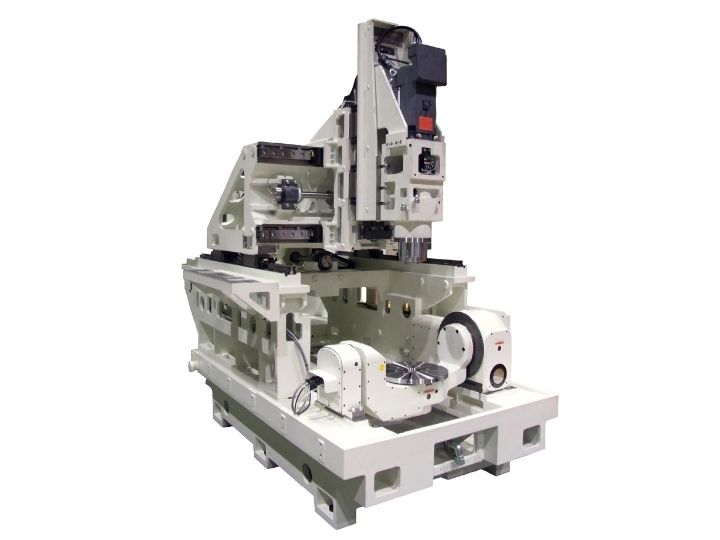

The Mytrunnion-4G incorporates a dynamic double column construction for outstanding support and stability even throughout the long Y-Axis stroke movement, offering exceptional cutting load characteristics and optimum accuracy. Symmetrical construction extends thermal stability over the Y-axis travel. The Arumatik-Mi CNC simplifies complex surface profiles and geometries faster, with superior surface finishes and optimum precision.

Uniquely Intuitive User Focused CNC Technology

The Arumatik-Mi control’s unique blend of advanced touch-screen icon driven and familiar conventional control technologies make this the CNC of the future. It is easy to use, fully customizable and is loaded with technology to perfect and simplify the user-machine experience.

Productivity Enhancing Features

- Ideal for ultra-high precision simultaneous 5-axis machining

- Positioning accuracy ±0.002mm (±0.000079”)/Full stroke, Repeatability ±0.001mm (±0.000039”)

- Powerful #40, 15,000rpm, 15HP direct drive, dual contact spindle – Optional HSK-A63 spindle configuration available.

- Ballscrew cooling system, 4th/5th axis scales and 67 million encoder technology offer unmatched accuracy in its class

- Expansive 21.7” Dia. X 15.7”H (550 x 400mm) work envelope beats the competition

- Highest grade Meehanite cast iron construction for superior vibration absorption improved surface finishes

- Automation ready! Optional field installed 12-station automated pallet system

- Arumatik-Mi CNC with ultra-high speed and high precision SSS (Super Smoot Surface) control with 8,190 block look ahead speeds

Mytrunnion-4GProduct Video

Check out our product video and explore our media library to see how our 5-axis machining centers can elevate your machining processes and unlock new levels of productivity!

Machining Centers

Looking for More Information?

We’re here to help!Whether you have questions or need guidance, please fill out the form.