September 1, 2014

Invest in Automation – Go Horizontal with Multi Pallets and Tools to Increase Productivity

Components of varying shapes and sizes cause one manufacturer to rethink their production techniques. With the addition of Kitamura’s Mycenter-HX400G Horizontal Machining Center with an 8-station automatic pallet changer, this Brea, CA manufacturer can now have as many as 20 parts set up and ready to go at one time. Most of the shops parts can now be machines in one operation, relieving the pressure.

June 1, 2014

Small Complex Component Machining

Superior surface finishes, a reduction in cycle times and high level accuracies for this New England job shop results in parts as close to perfect as possible – Courtesy of Kitamura.

August 1, 2013

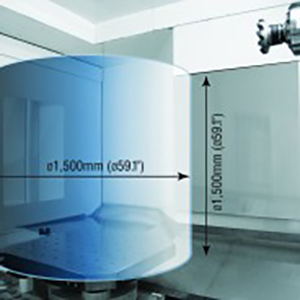

Kitamura’s Heavy Duty Mycenter-HX800iLTGA for Precision Custom Component Machining

Large Part Machining – Kitamura’s Mycenter-HX800iLTGA updates outdated equipment and offers this Ohio user improvements in speed, efficiency, precision and rigidity for their heavy duty machining requirements.

February 1, 2013

Machining Titanium with a Space Saving VMC and 5-Axis Retrofit Increases Metal Removal

A small shop added two new machines, each of which is more advanced than any of the previous machine tools the company has used, and one of them is a KITAMURA. Read on to share in the shops experiences and how high quality equipment makes an impact.