In the fast-moving world of manufacturing, flexibility is key to staying competitive. That’s why at Kitamura, we offer solutions across our full range of horizontal machining centers that allow you to start with a standard machine that’s proven to work perfectly for your current needs – and when you’re ready to expand, simply add pallet and tool automation systems in the field, turning your standard machines into powerful, unmanned production units. This flexible approach allows you to optimize your current workflow while ensuring your investment is scalable for future growth.

How it Works

- Start Simple: Purchase a standard machine and get familiar with its operation. This way, it's designed to preform efficiently right form the start, meeting your immediate production needs.

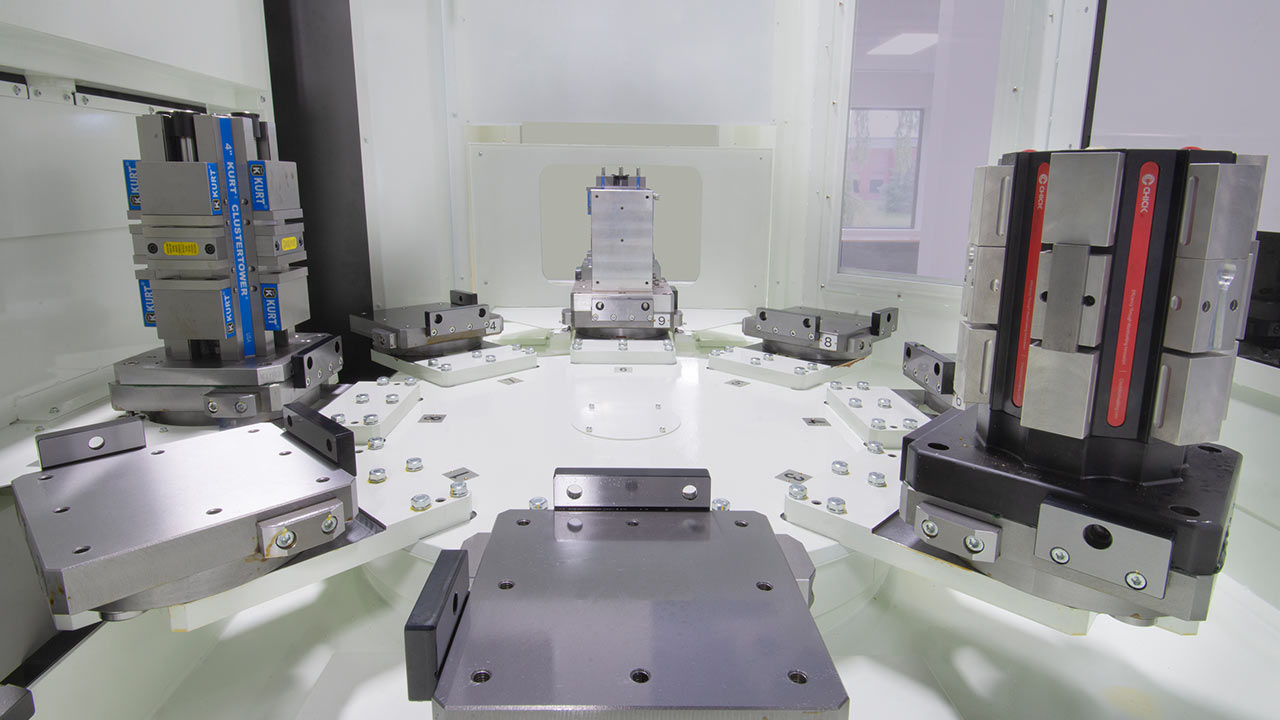

- Upgrade When You're Ready: As your requirements evolve, add automated pallet systems or tools changers at any time. No need for a full machine replacement - our systems are designed for seamless field retrofits.

- Customizable Solutions: Whether it's automated pallet handling to facilitate workload increases and maximize spindle uptime or tool changer capacity upgardes for uninterrupted runs, you can choose the solution that fits your growth path.

Why Choose This Flexible Approach?

- Cost-Effective: Invest in automation only when it makes sense for your business. Start with a high-quality, high-performance machine, and add automation later to meet growing demand.

- Scalable: Add functionality as your business expands. There’s no need to commit to complex automation until you are ready.

- Unmatched Efficiency: Our modular, field retrofitted automated pallet and tool systems enable unmanned operation, so you can boost productivity and operate 24/7 as your shop scales.

What our Customers are Saying

The field-installed 8-station pallet system has been a perfect fit for our short-run production. As a shop recognized by Modern Machine Shop as a TOP SHOP for machining technology, we rely on solutions that keep us agile. We can stage multiple setups in advance and keep the machine running between jobs with minimal downtime. It’s made us far more efficient without adding labor.

Alan Soucy

President – Advanced Precision Engineering

The throughput we get from these machines is incredible. With the 8-station pallet pools, we’re running 22 hours a day completely unmanned. The machines are fast and the fact that we could start standard and scale automation later made all the difference. We’ve got another pallet system on the way for machine #3.

Dave Wilcox

President – Ox Mfg

The modularity of the HX250iG was a HUGE benefit for our business. Adding the Pallet Pool and expanding the tool changer to 102 stations after the initial purchase and installation, enabled us to scale production up to meet customer demand on the fly while minimizing the impact on production. It also allowed us to reduce the number of VMCs on our floor, which in turn decreased the number of spindles and associated maintenance, ALL WHILE INCREASING OUTPUT!

James Kidon

President – Watts Engineering

Boost Efficiency with Modular Automation for Continuous Production

At Kitamura, our Vertical, Horizontal, and 5-Axis machining centers are built for flexibility—start with a standard machine and easily add automation to scale as you grow.