Kitamura Horizontal Machining Centers

Kitamura horizontal machining centers are engineered for manufacturers who demand exceptional speed, accuracy, and long-term reliability. With extra-large work envelopes and table sizes ranging from 250mm to 1250mm, our 4-axis horizontal machining centers are built for critical applications where ultra-tight tolerances are non-negotiable.

Proudly built in Japan, Kitamura horizontal machining centers feature precision hand-scraping techniques, solid Meehanite cast construction, solid box way design, and high-speed 4-step geared head spindles—delivering exceptional rigidity, thermal stability, and long-term repeatability. As a global leader in horizontal machining, Kitamura offers automation-ready platforms engineered for growth, with in-field expandability for additional tools, pallets, and full 5th-axis capability. Built to perform. Built to last.

Mycenter-HX250iG

(254 x 254mm) 10″ x 10″

Mycenter-HX300iG/400

(305 x 305mm) 12″ x 12″

Mycenter-HX400iG/500

(400 x 400mm) 15.7″ x 15.7″

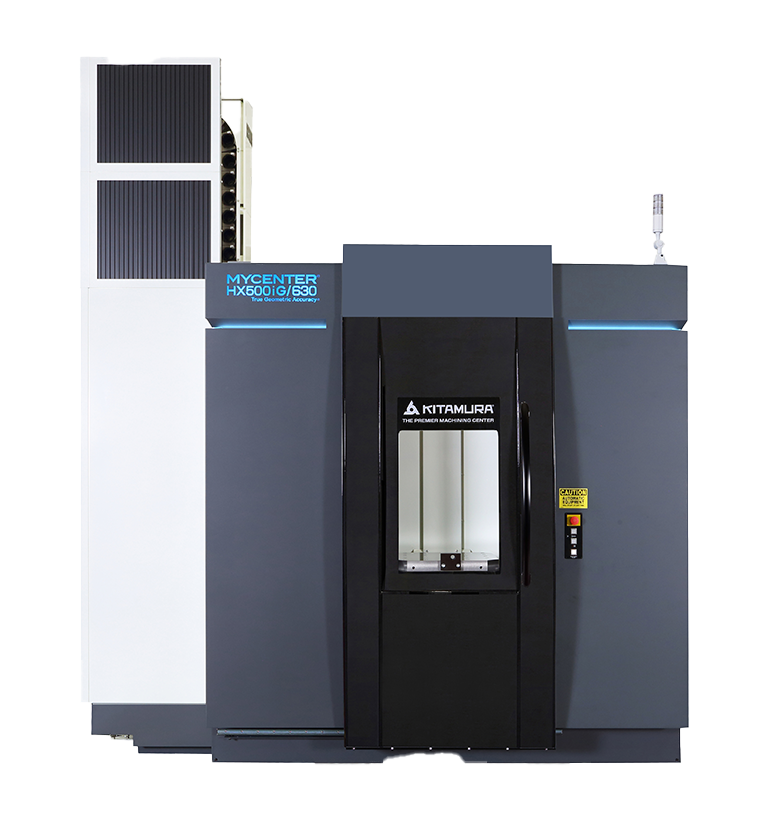

Mycenter-HX500iG/630 #40

(500 x 500mm) 19.7″ x 19.7″

Mycenter-HX500iG/630 #50

(500 x 500mm) 19.7″ x 19.7″

Mycenter-HX630G/800 #40

(254 x 254mm) 10″ x 10″

Kitamura Vertical Machining Centers

Kitamura Vertical Machining Centers are engineered for manufacturers who demand fast, precise, and reliable performance in a compact footprint. Designed to serve a wide range of industries from general machining and high-precision mold making to advanced high-tech applications our 3-axis vertical machining centers combine speed, accuracy, and heavy-duty cutting performance with unmatched build quality and operator-friendly design.

Constructed from rugged Meehanite castings with precision hand-scraped surfaces, Kitamura VMCs deliver the rigidity and thermal stability required for consistent, long-term accuracy. For high-production environments, models equipped with Kitamura’s patented 2-station Sparkchanger—a factory-installed 180° rotating pallet changer—offer seamless part loading and increased spindle uptime. With space-saving footprints and intuitive controls, Kitamura VMCs are easy to operate and built to perform—day in and day out.

Mycenter-Super Micron

(400 x 500mm) 15.7″ x 19.7″

Mycenter-3020G “Sparkchanger”

(500 x 860mm) 19.7″ x 33.9″

2-Station Automatic Pallet Changer

Mycenter-3020G

(500 x 860mm) 19.7″ x 33.9

Mycenter-2XV “Sparkchanger”

(400 x 560mm) 15.7″ x 22″

2-Station Automatic Pallet Changer

Mycenter-3XV

(500 x 860mm) 19.7″ x 33.9″

Mycenter-4XV

(510 x 1120mm) 19.7″ x 44.1″

Kitamura Double Column Machining Centers

Built to handle the demands of industry’s toughest challenges with ultra high accuracy, Kitamura’s 3-axis Bridgecenter series delivers massive cutting capacity with the strength and stability required for heavy table loads and large-scale components. Designed with a patented double column bridge-type structure and solid box way construction, these machines offer exceptional rigidity for aggressive roughing and fine-finishing alike.

Available with high-speed or high-torque spindle options and standard linear scale feedback, our double column machining centers ensure consistent accuracy across long machining runs. From aerospace and automotive to power generation, mold & die, oil & gas, space & defense, and semiconductor applications, Kitamura double column machining centers deliver precision where it matters most.

Bridgecenter-6G #40

(900 x 1800mm) 35.4″ x 70.9″

Bridgecenter-6G #50

(900 x 1800mm) 35.4″ x 70.9″

Bridgecenter-8G #40

(900 x 2500mm) 35.4″ x 98.4″

Bridgecenter-8G #50

(900 x 2500mm) 35.4″ x 98.4″

Bridgecenter-10G

(1370 x 3000mm) 53.9″ x 118.1″

Bridgecenter-12G

(1370 x 3500mm) 53.9″ x 137.8″

Kitamura 5-Axis Machining Centers

Redefining multi-surface precision. Kitamura’s 5-axis machining centers are built to handle complex geometries and demanding tolerances with fewer setups and higher throughput. Engineered for full simultaneous 5-axis contouring, our machines offer unrivaled accuracy, superior surface finishes, and reduced cycle times—perfect for intricate parts in aerospace, medical, and high-precision industries. Featuring ultra-rigid construction, high-speed spindles, and smooth control integration, they deliver long-term reliability and repeatable performance. Compact footprints, large work envelopes, and full automation compatibility make them ideal for manufacturers pushing the limits of efficiency and innovation.

MedCenter5AX

(Ø170mm) Ø6.7″

Mytrunnion-4G

(Ø400mm) Ø15.7″

Mytrunnion-5G

(Ø630mm) Ø24.8″

Mytrunnion-7G

(Ø1000mm) Ø39.7″

Supercell-300G

(Ø200mm) Ø7.9″

Supercell-400G

(Ø350mm) Ø13.8″

Looking for More Information?

We’re here to help!

Whether you have questions or need guidance, please fill out the form.