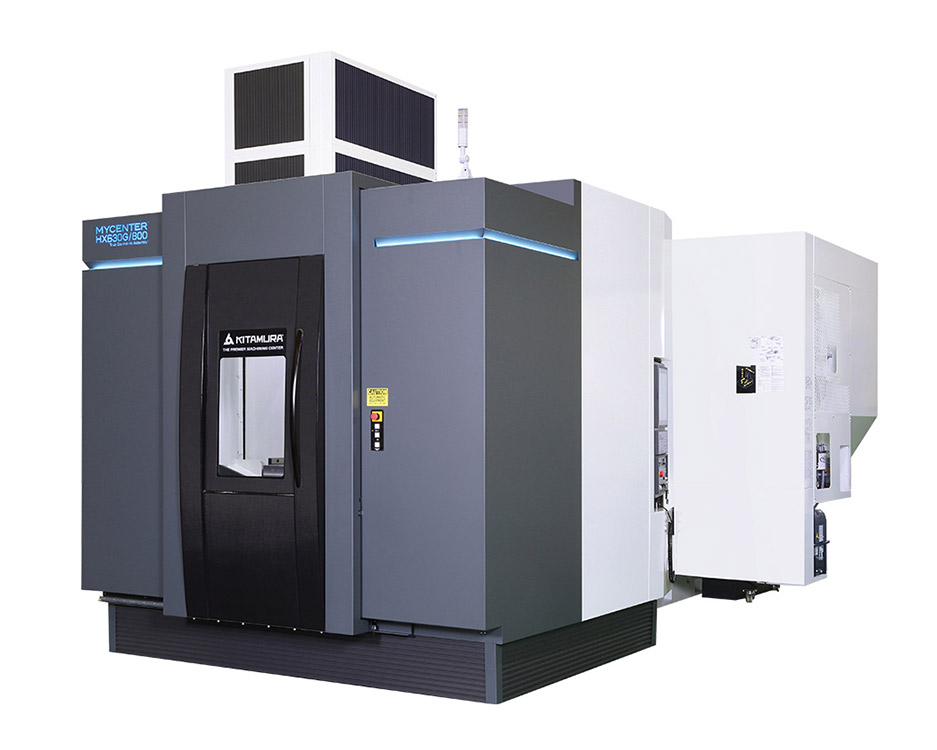

Bridgecenter-8G #40

Double Column 3-Axis Machining Center

Kitamura Bridgecenter-8G #40 double column vertical machining centers are designed for high-precision machining of extra-large, heavy components. Ideal for a wide spectrum of applications – from heavy-duty cutting of molds to high accuracy machining of high-tolerance parts.

Specifications

Product Detail

The basic construction of the Bridgecenter-8G #40 double column machining center consists of a bed type casting with square section support columns, incorporating a triangular section cross beam for an even distribution of weight during heavy cutting, standard linear scale feedback ensures optimum accuracy on a machine of this size. Construction of the Bridgecenter-8G #40 combines super-finish, ground-hardened solid box ways on all axes with high grade Meehanaite castings to deliver outstanding accuracy with excellent vibration damping capabilities.

A 20,000rpm, 4-step gear driven spindle is standard for lighter cuts with fine-finish capabilities at higher speeds. The Dual Contact Spindle design offers the benefits of greater machining rigidity, improved surface finish, higher cutting accuracy and extended cutting tool life.

Uniquely Intuitive User Focused CNC Technology

The Arumatik-Mi control’s unique blend of advanced touch-screen icon driven and familiar conventional control technologies make this the CNC of the future. It is easy to use, fully customizable and is loaded with technology to perfect and simplify the user-machine experience.

Productivity Enhancing Features

- Ideal for parts requiring heavier cutting loads and higher levels of precision and accuracy. Excellent for die/mold applications.

- Positioning accuracy ±0.002mm (±0.000079”)/Full stroke, Repeatability ±0.001mm (±0.000039”)

- Rigid Meehanite cast iron construction with induction hardened solid box ways

- #40, high speed, heavy duty 20,000rpm, 4-step geared, dual contact spindle

- Double column design with patented triangular crossbeam provides expansive work envelope and superior rigidity when compared with C-frame style machines

- Linear scale feedback in X,Y,Z axes

- Space saving and compact, the Bridgecenter-8G#40 measures only 3,494 x 5,86mm (137.6” x 230.9”) on your floor!

- 7,700Lb table capacity allows for the machining of larger and heavier workpieces

Bridgecenter-8G #40Product Video

Check out our product video and explore our media library to see how our 5-axis machining centers can elevate your machining processes and unlock new levels of productivity!

Machining Centers

Looking for More Information?

We’re here to help!Whether you have questions or need guidance, please fill out the form.