Mycenter-HX800G/1000

Horizontal 4-Axis Machining Center

The Mycenter-HX800G/1000 horizontal machining center is designed for high-value, close-tolerance machining of large components and fixtured tombstones. Extraordinary capacity, and superb accuracy make this an ideal choice in large capacity HMCs.

Specifications

4-Step Gear Driven

(T-T/C-C)

Product Detail

The Mycenter-HX800G/1000 heavy duty HMC Offers enhanced productivity and up to 1226N•m (904.2FT/LBS) of cutting torque for complex, high-accuracy, large part machining.

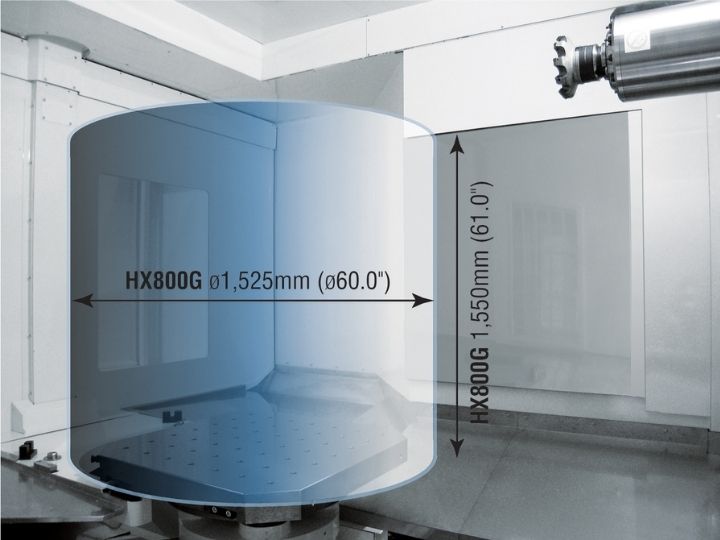

Designed for the precision necessary to produce close tolerance parts from the toughest of materials, the Mycenter-800G/1000 employs induction hardened solid box way design, combined with high grade Meehanite casting for the stiffness needed for true high precision hard milling. Guideways are equipped with ultra-high precision twin ball screws and twin servo motors that provide the capability of running speeds of 2,362ipm. An incredibly large work envelope with a max. workpiece size of Ø1,525mm (Ø60”) x 1,550mm (61”) H with standard 2-APC and full 4th axis fits within a space saving footprint. The total weight of the machine is a sturdy 65,400Lbs.

Uniquely Intuitive User Focused CNC Technology

The Arumatik-Mi control’s unique blend of advanced touch-screen icon driven and familiar conventional control technologies make this the CNC of the future. It is easy to use, fully customizable and is loaded with technology to perfect and simplify the user-machine experience.

Productivity Enhancing Features

- Expansive work envelope. 1,525mm (60”) Diameter x 1,550mm (61”) High

- Patented Twin Ballscrew and Dual Feedback Technology in X/Y/Z axis with 67 million pulse encoder and scale feedback in all axes

- Positioning Accuracy: ±0.002mm (±0.000079”)/Full Stroke,

Repeatability ±0.001mm (±0.000039”) - 2APC with high-speed full 4th axis rotary table. Ability to swap out to 1,000mm tables in field

- Ultra-high-speed processing Arumatik-Mi CNC with Super Smooth Surface control

- High speed 12,000rpm, 4-step gear driven, dual contact spindle – Optional 8,000rpm high torque spindle available

- Optional 6/8 APC and additional tool upgrades available – Field expandable!

- World’s fastest 60m/min (2,362ipm) rapid feed rates on SOLID BOX WAYS.

Mycenter-HX800G/1000

Real-World Results

Learn how our customers are realizing significant improvements in machining performance and efficiency.

Machining Centers

Looking for More Information?

We’re here to help!

Whether you have questions or need guidance, please fill out the form.