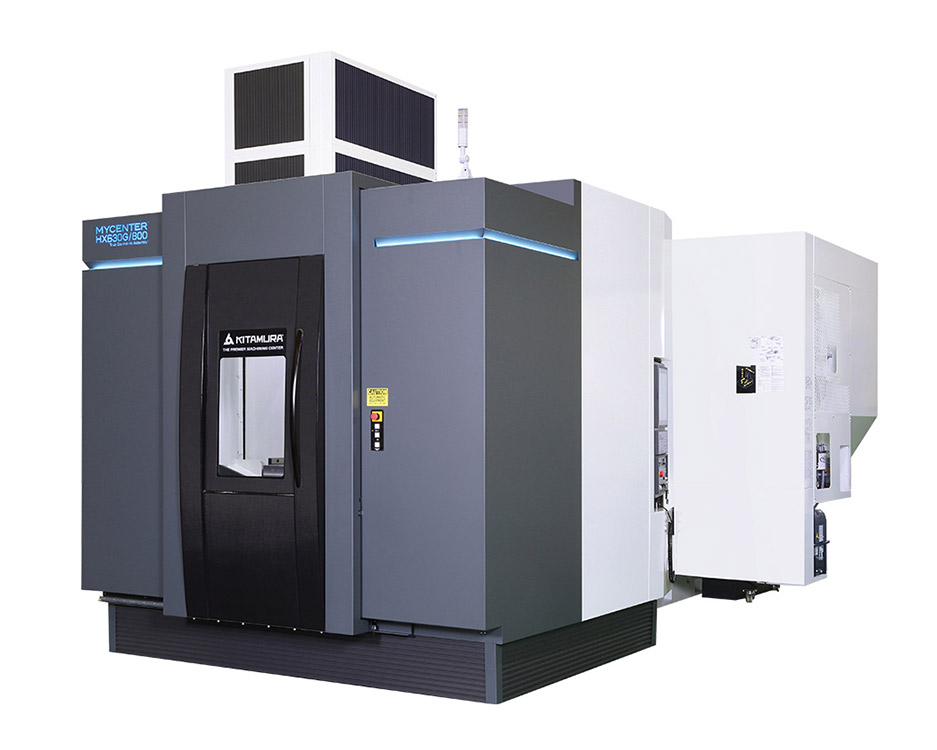

MedCenter5AX

Vertical 5-Axis Machining Center

The MedCenter5AX high speed simultaneous 5-axis vertical machining centers offers unrivaled accuracy in an ultra-compact footprint. It’s the perfect 5-axis CNC for all your smaller complex parts and micro machining.

Specifications

Product Detail

Kitamura’s versatile MedCenter5AX is an ultra-high precision, 5-axis simultaneous vertical machining center that offers unparalleled accuracy and speed for expanded machining capability in the machining of highly complex small to medium, multi-sided parts in one set-up. The machine’s maximum stiffness, flexibility, and cutting capability make it an optimal choice for manufacturing precision parts for the medical, aerospace, automotive and telecommunications industries and micro machining.

Automation ready with the ability to field retrofit a 20-station APC and a high performance 120 tool ATC – all in a super compact, space saving footprint, this small 5-axis machining center works overtime to eliminate waste, increase productivity and lower costs.

Uniquely Intuitive User Focused CNC Technology

The Arumatik-Mi control’s unique blend of advanced touch-screen icon driven and familiar conventional control technologies make this the CNC of the future. It is easy to use, fully customizable and is loaded with technology to perfect and simplify the user-machine experience.

Productivity Enhancing Features

- Ideal for ultra-high precision simultaneous 5-axis machining of small medical parts, micro machining

- Positioning accuracy ±0.001mm (±0.000039”)/Full stroke, Repeatability ±0.0005mm (±0.00002”)

- Compact design fits within a 4’ x 7’ footprint

- Powerful high-speed 30,000rpm HSK-E40 25HP integral drive spindle

- 40 tool, fixed pot ATC with maximum tool weight of 4.4Lbs. Optional 120T available

- High accuracy package – linear & rotary scales, 67 million pulse encoder technology, 16mm fine pitch ballscrews

- Automation ready! Optional 12 and 20/24 station pallet systems available

- Arumatik-Mi CNC with ultra-high speed and high precision SSS (Super Smoot Surface) control with up to 8,190 block look ahead speeds

MedCenter5AXProduct Video

Check out our product video and explore our media library to see how our 5-axis machining centers can elevate your machining processes and unlock new levels of productivity!

Machining Centers

Looking for More Information?

We’re here to help!Whether you have questions or need guidance, please fill out the form.