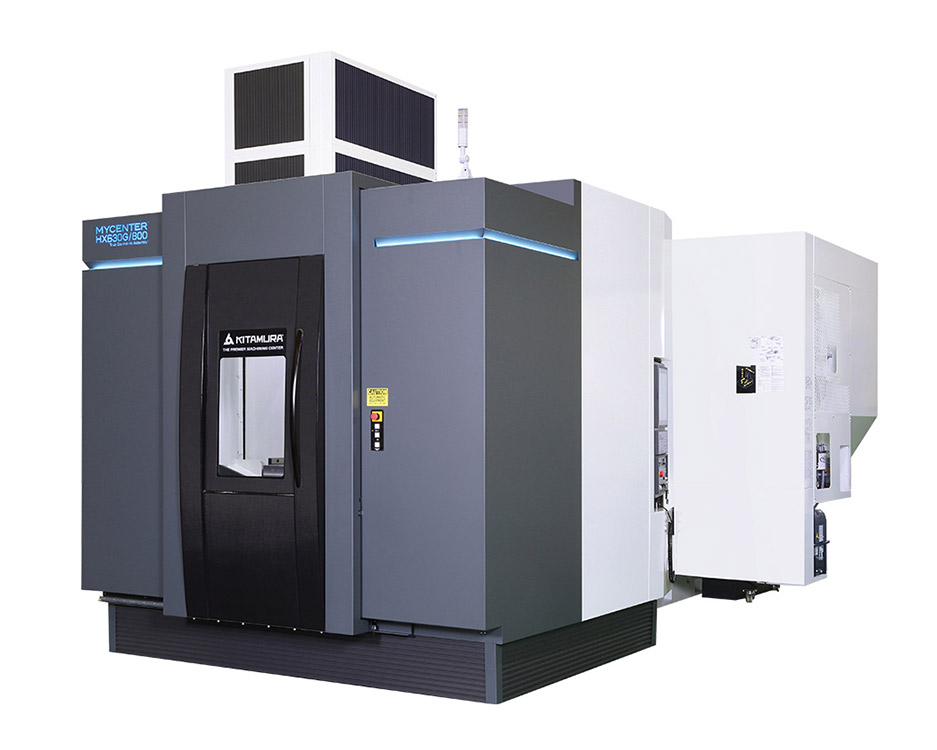

Mycenter-HX400iG/500

Horizontal 4-Axis Machining Center

The Mycenter-HX400iG/500 delivers the world’s fastest 400mm mid to large size horizontal machining technology. Superior in its solid box way design and ultra-high precision for your most challenging workpieces.

Specifications

(T-T/C-C)

Product Detail

Setting a new standard in mid-size, high-precision horizontal machining.

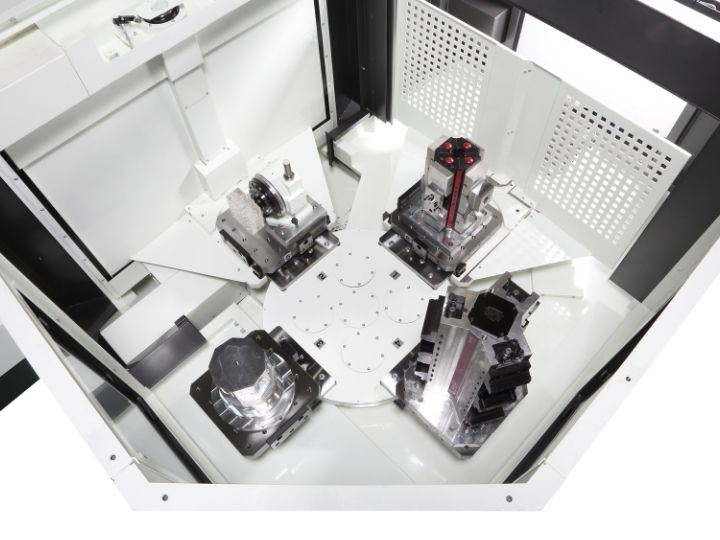

The Mycenter-400iG/500 delivers the ultimate in state-of-the-art HMC performance. Solid box guideways, ballscrew cooling, IAC 1 and scale feedback on all axes offer unmatched accuracy and optimum stability. A standard 2-station APC coupled with full 360-degree 4th axis capability with 45,000deg/min (125 min¯¹) rapids mean faster part turn around and more production per pallet load. Standard features include blazing 60m/min (2,362ipm) rapids, high speed 15,000rpm spindle, double decker conveyor and filtration system, and high-speed processing Arumatik-Mi CNC make this space saving mid-size HMC your go to for a variety of machining applications.

Automation ready, with the ability to add modular pallet and tool systems in the field for non-stop production.

Uniquely Intuitive User Focused CNC Technology

The Arumatik-Mi control’s unique blend of advanced touch-screen icon driven and familiar conventional control technologies make this the CNC of the future. It is easy to use, fully customizable and is loaded with technology to perfect and simplify the user-machine experience.

Productivity Enhancing Features

- Expansive work envelope. 630mm (24.8”) Diameter x 790mm (31.1”) High

- Ballscrew cooling in all axes and IAC System 1 thermal compensation system

- Positioning Accuracy: ±0.001mm (±0.000039”)/Full Stroke,

Repeatability ±0.0005mm (±0.00002”) - 2APC with high-speed 4th axis rotary table, DD motor driven, 45,000deg/min rapids

- Ultra-high-speed processing Arumatik-Mi CNC with Super Smooth Surface control

- Powerful 15,000rpm, dual contact spindle – Optional 20,000 spindle available

- Optional 6/8/14/21 APC and additional tool upgrades available – Field expandable!

- World’s fastest 60m/min (2,362ipm) rapid feed rates on SOLID BOX WAYS.

Mycenter HX400iG/500Product Video

Check out our product video and explore our media library to see how our horizontal machining centers can elevate your machining processes and unlock new levels of productivity!

Machining Centers

Looking for More Information?

We’re here to help!Whether you have questions or need guidance, please fill out the form.