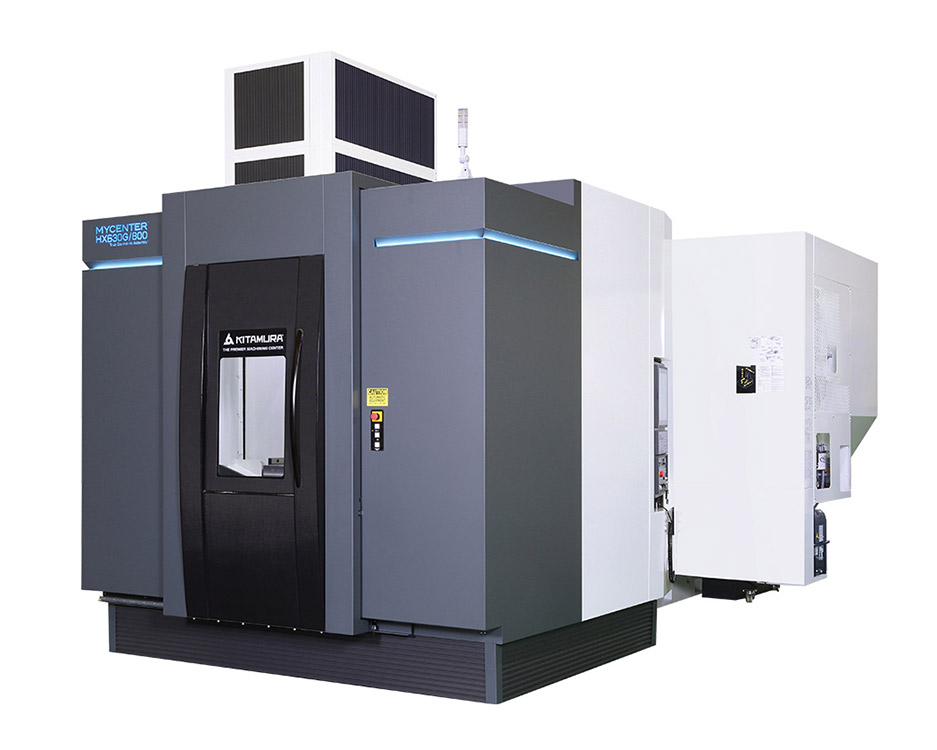

Supercell-400G

Horizontal 5-Axis Machining Center

The Supercell-400G 5-axis Horizontal Manufacturing Cell features multi-pallet and multi-tool configurations for high-mix or repeat parts, running largely unattended for maximum machine utilization.

Specifications

Product Detail

The simultaneous 5-axis machining solution to today’s complex production demands.

Get the competitive edge and put your machine tool investment to work day and night, manned or unmanned with the Supercell-400G 5-axis Horizontal Manufacturing Cell. This space saving production center offers a standard 20 station pallet changer and 190 tool configuration to run several like or unique parts at a time, largely unattended for full utilization of your machine too. Full simultaneous 5-axis capabilities allow for machining of a part, complete, in one operation while the unique floor layout affords easily visible and easily accessible part set-up and quality control. Standard ballscrew cooling system, solid box way design, linear & rotary scaled feedback and IAC System 1 guarantee positioning accuracy of +/-0.002mm (+/-o.000079”)/Full Stroke, Repeatability +/-0.001mm (+/-0.000039”).

Options of up to 80 pallets and up to 290 tools can be added for greater machining flexibility in unmanned operation.

Uniquely Intuitive User Focused CNC Technology

The Arumatik-Mi control’s unique blend of advanced touch-screen icon driven and familiar conventional control technologies make this the CNC of the future. It is easy to use, fully customizable and is loaded with technology to perfect and simplify the user-machine experience.

Productivity Enhancing Features

- Horizontal 5-axis configuration allows flexibility for single set-up, unmanned machining

- 20-station automatic pallet changer with load/unload station. Up to 120 pallets as an available option

- Ultra-high positioning accuracy ±0.001mm (±0.000039”)/Full stroke, Repeatability ±0.0005mm (±0.00002”)

- Ideal for both unmanned one-off and high quantity production

- Energy saving, high performance, high speed 20,000rpm, 4-step gear driven dual contact spindle ensures rigidity

- Work handling system reduces pallet load & unload time, allowing for just-in-time delivery

- Highest grade Meehanite cast iron construction with induction hardened solid box ways

Supercell-400G

Success with the Kitamura Supercell Series

earn how the Supercell Series 5-Axis HMC’s deliver exceptional performance and reliability in real-world applications.

Machining Centers

Looking for More Information?

We’re here to help!

Whether you have questions or need guidance, please fill out the form.